Fully Automated Optimization Engine

ZF Employs an Optimization Engine for the Development of Modular Motor Platforms

About ZF

ZF is a global technology company supplying systems for passenger cars, commercial vehicles, and industrial technology, enabling the next generation of mobility. ZF allows vehicles to see, think and act. In the four technology domains of Vehicle Motion Control, Integrated Safety, Automated Driving, and Electric Mobility, ZF offers comprehensive product and software solutions for established vehicle manufacturers and newly emerging transport and mobility service providers. ZF electrifies a wide range of vehicle types. With its products, the company contributes to reducing emissions, protecting the climate, and enhancing safe mobility.

Their Challenge

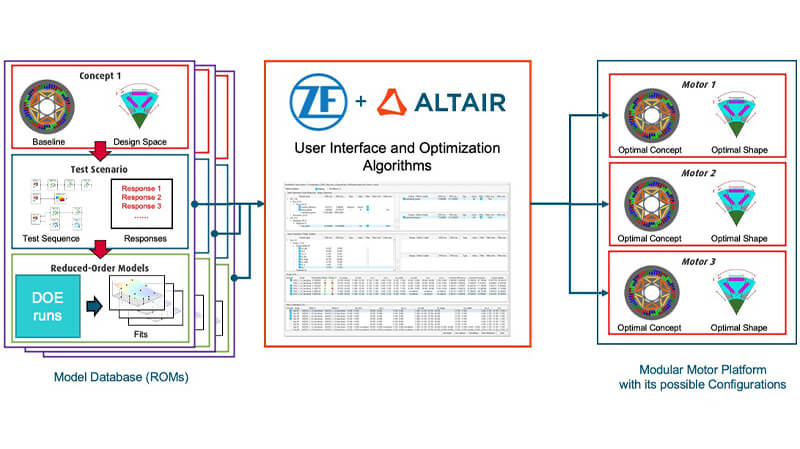

ZF develops a wide variety of e-motors and e-drives for a broad spectrum of automotive customers. To optimally incorporate development and production costs from the outset, their designers must find solutions to maximize shared parts within the given requirements for the motors. To achieve this, ZF groups products into motor programs that have similar design and production objectives and identifies common design features that can be used across a modular motor platform. However, the potential scope of motor configurations is enormously extensive. With a theoretically infinite number of motor configuration possibilities, it would be impossible with human resources to manually select an optimal combination of motor configurations for a motor platform while accounting for all requirements. Consequently, ZF needed a simulation and data-driven solution that would empower them to consider shared parts, costs, and further constraints to automatically find best configurations for a modular motor platform.

Modular motor platform optimization

Modular motor platform optimization