Employing Simulation-Driven Solutions to Develop an Iconic Sculpture

New Zealand lore tells of the great navigator Ngatoroirangi, a Māori high priest who originally hailed from Hawaii. While exploring New Zealand, he became stuck in a snow blizzard atop Mount Tongariro. Desperate for help, he called out to his family in Hawaii to send him warmth and fire. They answered his call in the form of the geothermal hot springs we can observe in and around the region today.

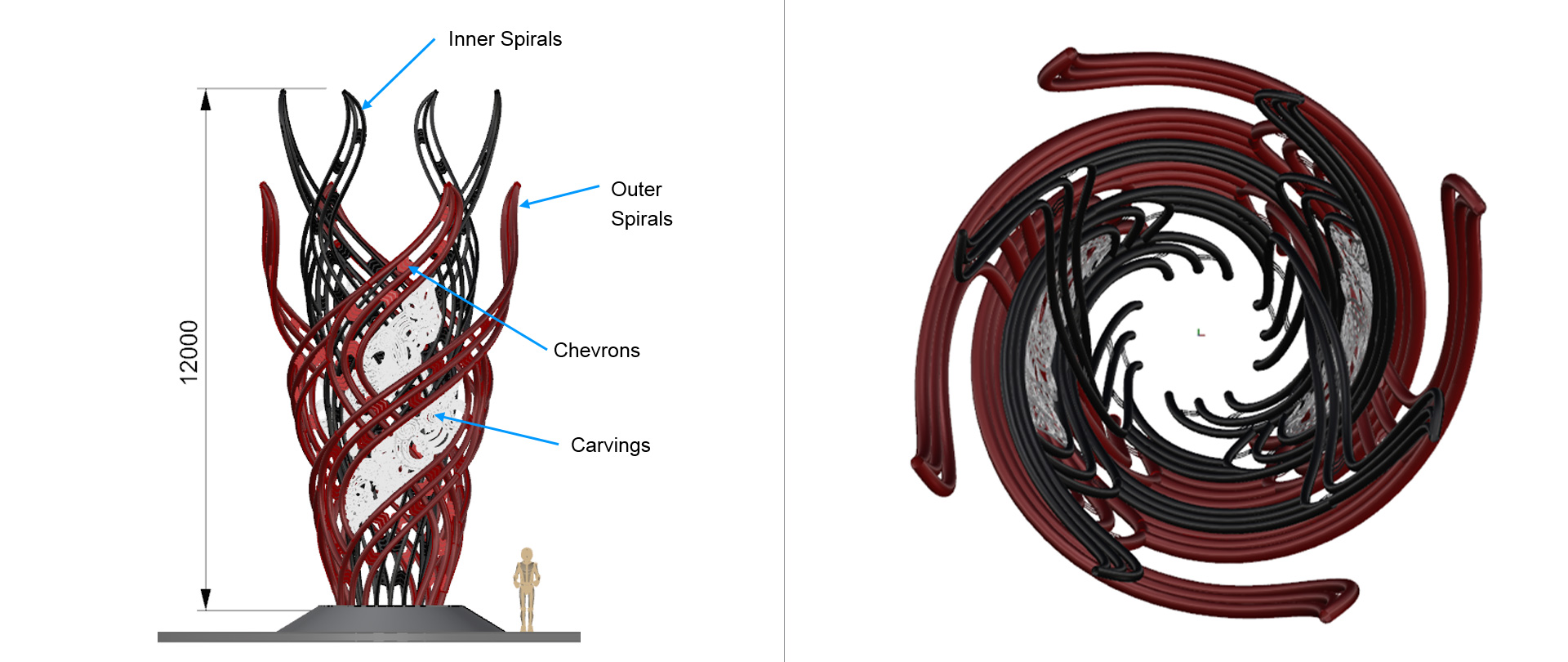

The town of Rotorua is a popular tourist destination, renowned for its geothermal activity and Māori culture. In the Whakarewarewa Valley, the 30 meter-tall Pohutu Geyser erupts many times daily. The erupting water and steam of the geyser, along with the harrowing story of Ngatoroirangi, served as inspiration for the curved structure of the gateway sculpture design by Stacy Gordine from the New Zealand Māori Arts and Crafts Institute.

The local council of Rotorua, New Zealand approved upgrades to the town’s road network, including a large roundabout at the Southern border. This presented Rotorua with the unique opportunity to create a showcase art installation to serve as a gateway, welcoming visitors and residents into the town.

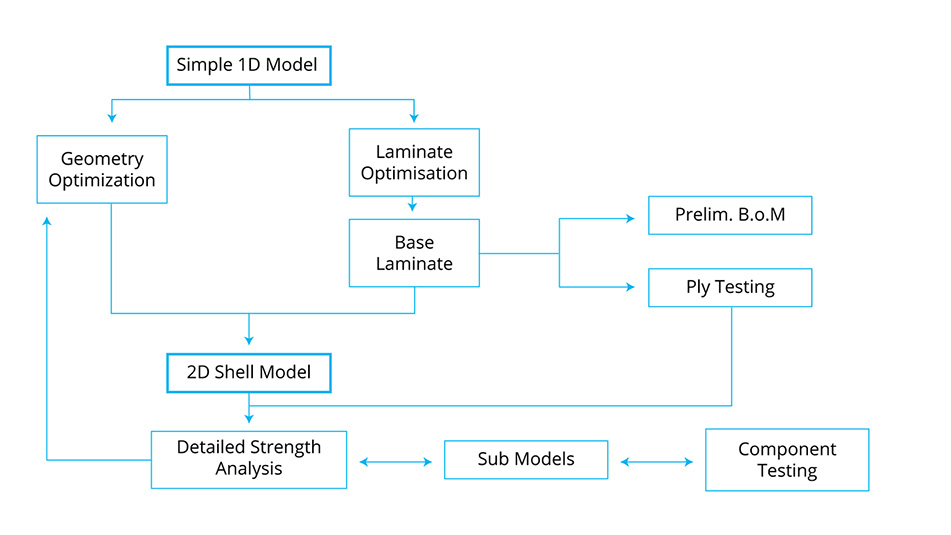

To help realize this ambitious project, the town elicited the help of global composites company, Gurit.

Based in Wattwil, Switzerland, Gurit is a developer and innovator in the composites industry as well as the leading global supplier of composite materials, engineering services, tooling equipment, and select parts and systems. Gurit has over 30 years’ experience in the practical application of composites across various market sectors and projects, from small parts to large-scale structures, combined with a unique technical approach which enables them to offer a complete set of composite solution.