BMW Group Invests €10 Million in German Additive Manufacturing Campus

The multinational automotive BMW Group has invested €10 million (approximately $12.3 million) in an Additive Manufacturing Campus scheduled to open early 2019.

A 6,000 square meter facility, the new Additive Manufacturing Campus will focus on prototyping, series production of parts, and customized solutions for the automotive industry.

Udo Hänle, Head of Production Integration at BMW comments, “Our new Additive Manufacturing Campus will concentrate the full spectrum of the BMW Group’s 3D printing expertise at a single location. This will allow us to test new technologies early on and continue developing our pioneering role.”

Pedal to the metal for 3D printing at BMW

According to BMW 3D printing is an integral part of research and development at the company. At sites in Spartanburg (U.S.), Shenyang (China) and Rayong (Thailand) BMW already uses 3D printing for prototyping purposes.

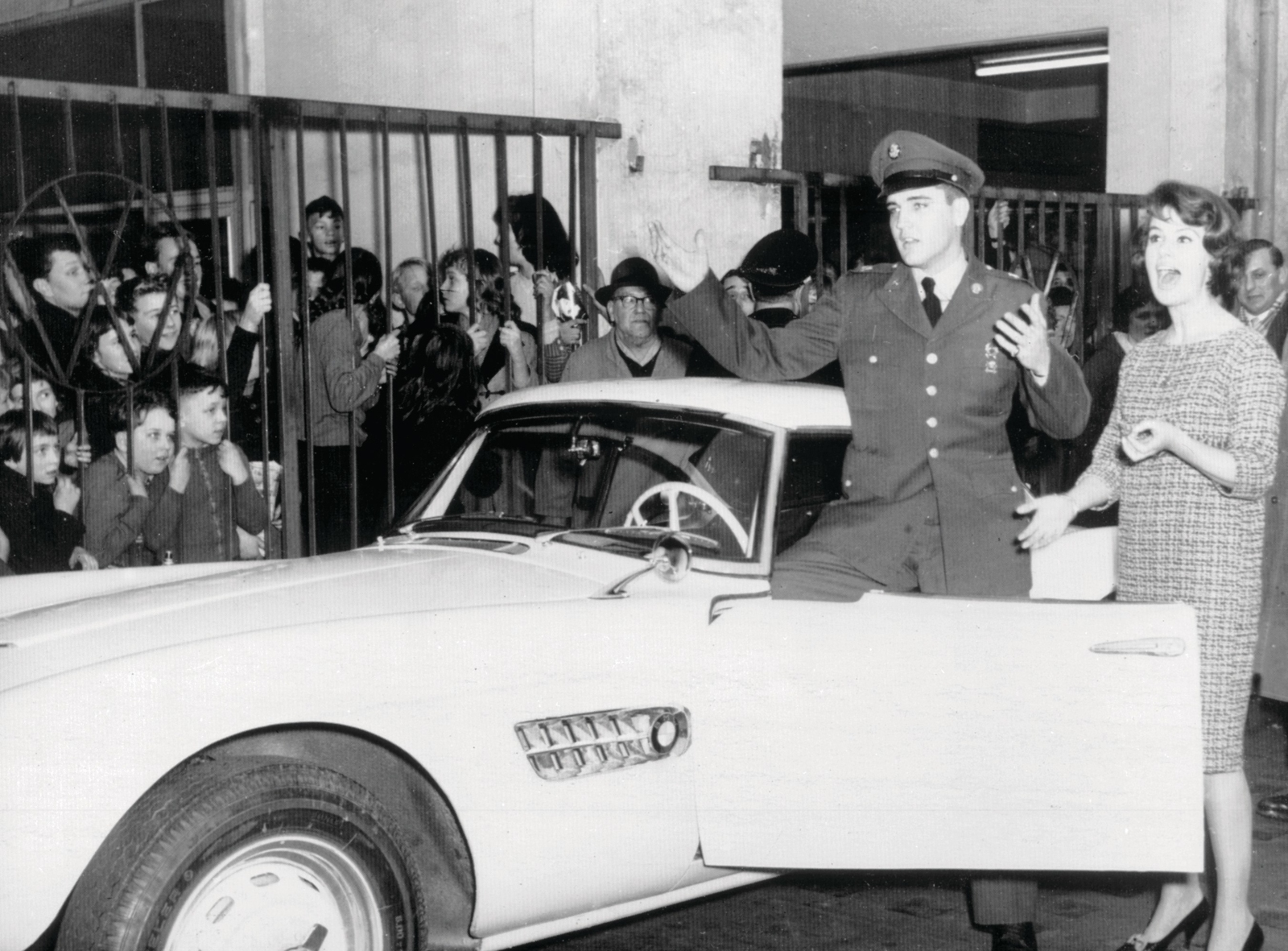

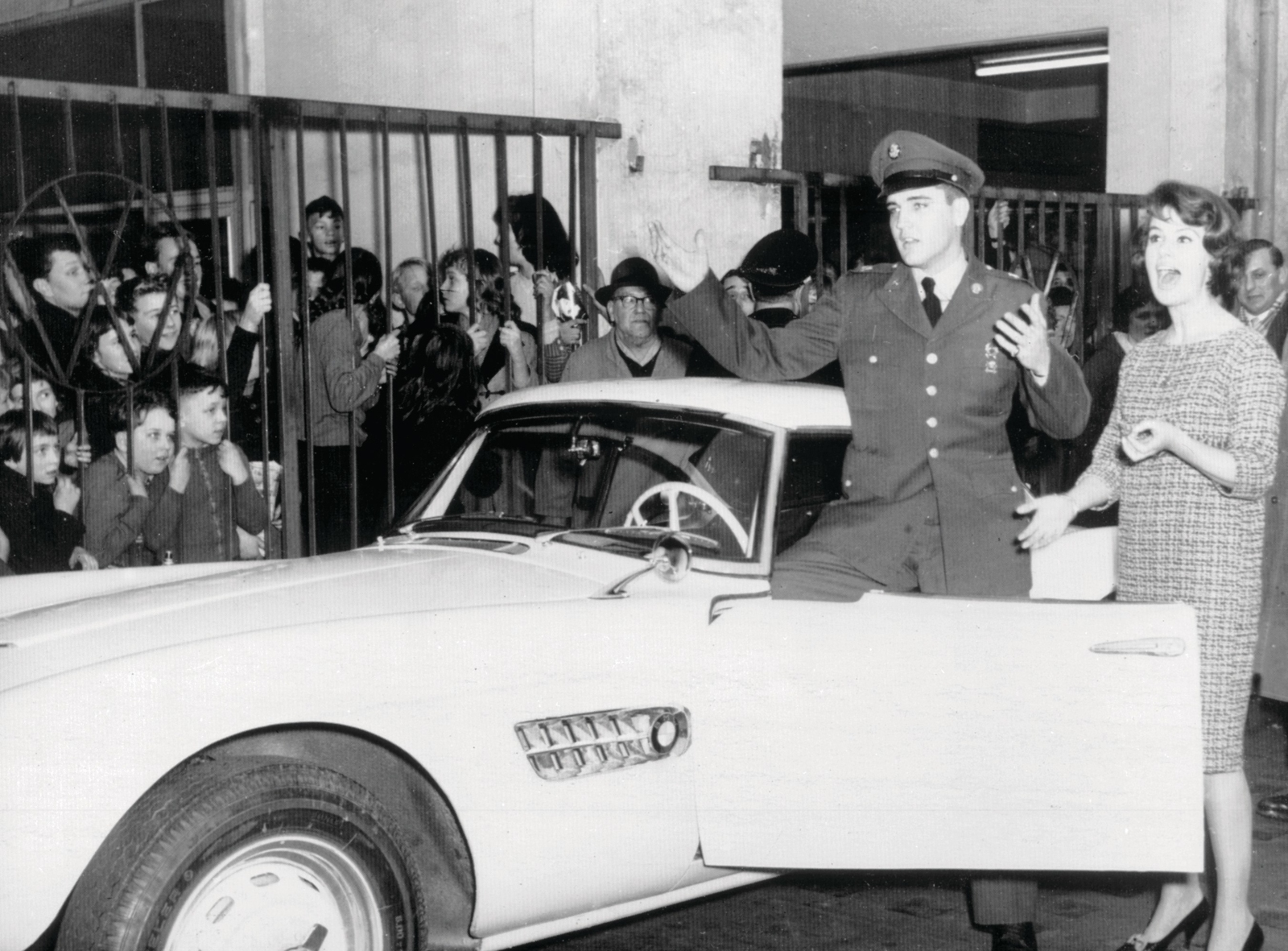

Recently, under the BMW Group umbrella, the MINI car brand introduced a commercial 3D printing service that allows customers to specify decals for the lights and dash of their cars. Fellow group brand Rolls-Royce has been applying 3D printing to the production of its bespoke vehicles. And the company has also applied 3D printing to the restoration of Elvis Presley’s BMW 507.

Read the full story on 3dprintingindustry.com.

A 6,000 square meter facility, the new Additive Manufacturing Campus will focus on prototyping, series production of parts, and customized solutions for the automotive industry.

Udo Hänle, Head of Production Integration at BMW comments, “Our new Additive Manufacturing Campus will concentrate the full spectrum of the BMW Group’s 3D printing expertise at a single location. This will allow us to test new technologies early on and continue developing our pioneering role.”

Pedal to the metal for 3D printing at BMW

According to BMW 3D printing is an integral part of research and development at the company. At sites in Spartanburg (U.S.), Shenyang (China) and Rayong (Thailand) BMW already uses 3D printing for prototyping purposes.

Recently, under the BMW Group umbrella, the MINI car brand introduced a commercial 3D printing service that allows customers to specify decals for the lights and dash of their cars. Fellow group brand Rolls-Royce has been applying 3D printing to the production of its bespoke vehicles. And the company has also applied 3D printing to the restoration of Elvis Presley’s BMW 507.

Read the full story on 3dprintingindustry.com.