How High-Performance Design is Driving Innovation in Civil Engineering

For civil engineers and architects, the ability to analyze a structure’s design and its performance is key at the very start of development. Traditionally, physical prototyping for buildings can take months due to design reiterations and outdated design processes. Because of the size and complexity of architecture, engineering, and construction (AEC) projects, designing new structures without a practical workflow makes it almost impossible to efficiently develop and validate new designs. The time it takes to validate a structure’s design is extensive due to feedback needed between architectural teams and having to perform manual CAD simplification within simulation software.

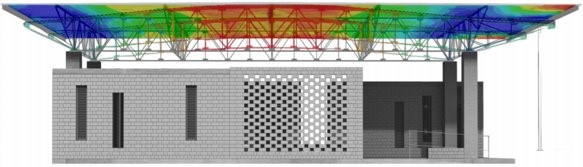

Applying simulation at the beginning of a project is the solution to slowed project timelines and potentially enduring big penalties due to delayed deliveries. Through Altair’s multi-disciplinary optimization workflow, users are able understand the structural performance of architectural designs earlier. A high-performance design (HPD) approach allows civil engineers to gain rapid insights about how a structure will perform under different loads, stresses, and weather conditions. Innovative, functional structures can be created with Altair technology that allows companies to accelerate design cycles, reduce building costs, and virtually validate designs while mitigating risk. All geometry simplification and both manual and automated meshing can be performed within Altair’s simulation technology.

Whether a user is optimizing a structure at the component level, or performing a complex system-level study, a high-performance design approach enables teams to create functional and long-lasting structures without having to compromise creativity.

Explore design alternatives in complex structures

Because of the project pressures that come with AEC design cycles, design teams want to be able to create fast, feasible designs without having to worry about switching between CAD and CAE models to assess the viability of design iterations. Altair SimSolid™ is an innovative solution for analyzing fully featured CAD assemblies in minutes without meshing.

Learn more about how SimSolid has been used for various architectural applications.

“Using SimSolid was phenomenal. We cut the traditional design cycle time by 50%, and were still running full CAD assembly in minutes to seconds. SimSolid was a key enabler to evaluate multiple design alternatives on the fly. We significantly reduced the engineering hours needed for full assembly, allowing us to meet the deadline with a robust and feasible design.” - Atanas Zhelev, Digital Architects

For large, complex assemblies of steel structures, Altair’s high-performance design approach gives designers accurate simulation results in minutes without the need for geometry simplification. With SimSolid’s automatic bolt and nut recognition, along with automatic contact and weld creation, users no longer need to worry about modifying CAD and sacrificing accuracy in order to analyze these massive structures. These insights allow engineers to foresee better alternatives in large structural models and rapidly evolve designs within existing project timelines. With SimSolid, design teams can easily perform multiple iterations of their most complex parts and explore multiple alternatives of large assemblies.

Optimization made easier

When designing complex structures, teams are looking to create the most efficient shapes without having to endure huge material and building costs. By implementing an optimization process to the design cycle, material usage can be significantly reduced and therefore save teams big costs. Applying optimization techniques early during simulation allows designers and engineers to leverage advanced optimization techniques like size optimization, deployed within bars and plates models to optimize beams and columns’ profiles and walls’ thicknesses. Or with topology optimization, the same material growth patterns found in biological forms can be used to explore complex loading patterns to achieve optimal structural performance and eliminate material redundancies within designs.

Here are five different ways you can optimize your architectural design.

Customer success with Altair HPD: the art of high-performance design

In 2015, architectural design firm Zaha Hadid Architects took to a challenge of re-designing the Neue Nationalgalerie, an art gallery located in Berlin. For concept and design creation, the group utilized Altair simulation products to visualize their design proposal. In order to preserve the building’s distinct features and artistic expression, designers optimized the structure’s material usage using Altair HyperWorks™ to reduce component weight while keeping original characteristics intact.

Doppelmayr Seilbahnen is a manufacturer of ropeways and innovative transport systems for urban and ski areas. Needing to ensure their products are of the highest quality and function properly, they used Altair tools to analyze and redesign a bracket within their lift station building. Previously, the seam weld of this bracket had failed a critical vibration test and so it was necessary to improve the design of the component to increase the strength and improve the fatigue-life of the connection, all while reducing weight.

SimSolid’s solver gave the users structural analysis results in seconds to minutes without the need for manual meshing or geometry cleanup. After identifying the problem area, geometry modifications were made directly to the model, reanalyzed in SimSolid, then compared against the initial design. All actions were carried out without the need to switch and translate between multiple software interfaces, allowing them to make rapid design decisions.

Use high-performance design to your advantage

There’s no need for unnecessary testing costs and wasted time if a high-performance design approach is used correctly in your workflow. Enhancing your existing design process can sound daunting, but with Altair’s holistic optimization workflow, you can validate structures and compare multiple design iterations within the same platform. Altair’s high-performance design tools for architecture make it easy to meet project deadlines and achieve ultimate product performance.

Altair provides simulation solutions for structural analysis and optimization as well as meshing, blast analysis, and CFD. Click here to see how design firms have used these solutions to their advantage.