Emerging Technologies and Design for Manufacturing – The Metal Casting Process

“Additive”, has lately made the word ‘manufacturing’, totally cool again!

It is a breath of fresh air for the traditional manufacturing process with a rapidly growing share of 3D printing challenging conventional thinking.

A few days ago I took a flight out of Flint, Michigan which was once the epicenter of manufacturing, luring those near and far promising automotive riches. Over the years a lot has transpired. I was contemplating how the manufacturing industry has the ability to once again put certain regions back on the map, this time around catering to a generation that prides itself on personalization and low tolerance for high emissions.

Product design is rapidly changing to keep pace with the desires of the younger generation, and just to elaborate, in the recent IKB Deutsche Industrial Bank report on manufacturing, the top three trends that caught my attention were;

- Light weighting is the #1 priority in the automotive industry today (largest consumer of manufactured components), especially to meet the new emissions standards

- Conventional low strength Steels are predicted to dip down below 20% of total usage by year 2030 (dropping from 70% in the 1970s)

- Alternative materials like Aluminum and Magnesium will be on the rise (along with high strength steels)

As the boundaries of product design are being stretched by an ever growing desire to lighten structures first in aerospace, and now in the automotive industry; the importance of upfront manufacturing feasibility has risen to new heights. The emergence of alternative materials such as: Magnesium, and Aluminum, along with alloys like ZAMAC as well as the addition of new additive manufacturing techniques to 3D print patterns and dies, have brought new process challenges along with immense opportunities to this struggling industry. It will be increasingly difficult for manufacturing suppliers to differentiate and still keep their profit margins, if they do not maximize the potential to use the latest technologies in simulation tools.

Under these trends, a holistic approach towards the entire product design lifecycle is then paramount as we push the envelope of design with newer materials and manufacturing processes to meet the challenges. We need environments that make great products that are faster to design, better in performance and at the same time easier to manufacture. Is it even possible?

In a series of blogs I will be focusing on different emerging technologies that work in tandem with traditional manufacturing methods and has tremendous potential to breathe new life into this industry. In this first blog of the proposed series, I would like to draw your attention towards the metal Casting process with an attempt to articulate the challenges & opportunities; and the benefits of applying simulation driven process to address them.

Investment Casting: Marriage of Additive and Traditional Manufacturing

An increased number of 3D printings are in rapid rise in traditional manufacturing industry and specifically for making casting patterns. Please refer to an earlier blog on this subject by Mirko Bromberger (3D Printing and Simulation-Driven Design for High Performance Castings) wherein it was shown how a part can be designed from the ground up using topology optimization for light weighting and then worked on streamlining the desired casting process.

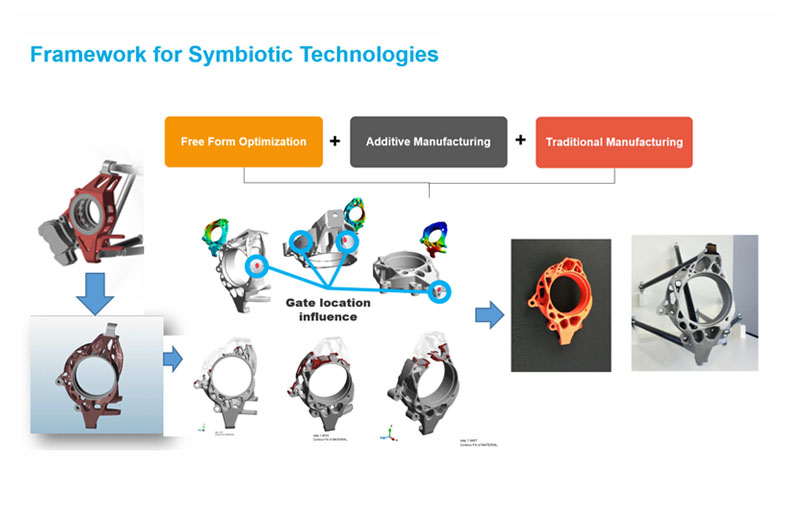

As shown in the graphic below, the entire process is highlighted wherein the best of breed technologies were combined together; topology (free form) optimization for light weighting, 3D printing for making the pattern and using investment casting for making a traditional casting. One essence of this entire exercise is that to produce innovative products, manufacturing feasibility has to be embedded into the product design process upfront.

Secondly a framework needs to exist wherein fast, easy, accurate information can be provided to the design and manufacturing Engineers right at their fingertips to meet the challenges, through the entire product design phase irrespective of what stage they are at. I strongly feel that to meet the quality standards, minimize catastrophic (cancerous) casting defects and to improve productivity of castings, manufacturing feasibility has to be part of the design process. The pace of product innovation can be severely hampered if designs are thrown over the fence to foundries, to take the entire burden of making quality components, while still being able to meet their margins and be profitable.

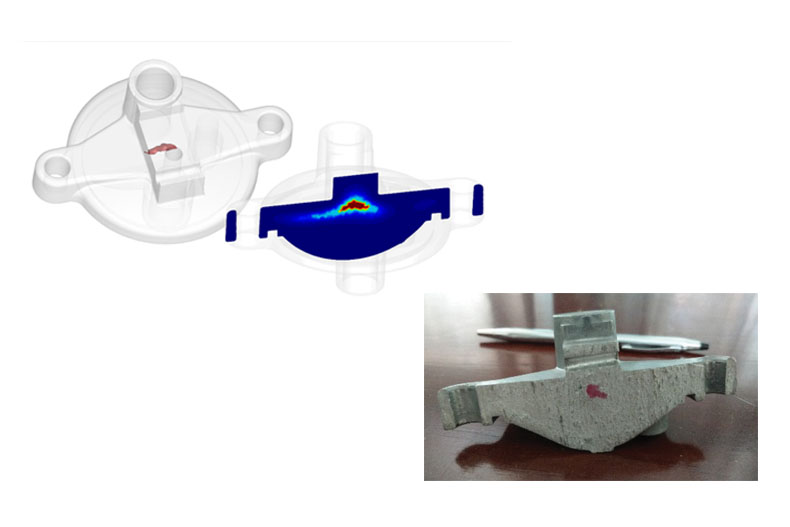

The above problems can be solved in an environment that is easy to use, while being accurate in capturing the physics, and also is affordable (to ramp up and use effectively). Altair’s solidThinking Inspire is already making the industry turn its head on topology optimization, by providing technologies upfront to the designers, hiding all the complexities. In keeping with the same philosophy, our latest release of Click2Cast 4.0, helps address casting problems effortlessly through process driven templates for all the above casting process including investments castings.

Our customers love the fact that they can run Click2Cast within their design process right from the beginning, wherein product designers can define any location on the product as in-gates (areas from where metal flows into the product) for castings to drive simulation, without having to wait for detailed process experts to design them for them. They can also visualize areas of potential porosity, thus guiding the process engineers to appropriately do the detailed design of the runners and risers and the gating systems. The process engineers can also easily choose the process being used through guided templates to set their problems and run the entire simulation on their own computers.

Click2Cast environment allows users to easily perform their entire casting simulation in 5 steps, thus bridging the communication gap within the entire product supply chain to make quick decisions, while utilizing the best process and simulation tools for the most challenging designs.

Below you will find a primer on Castings that would greatly supplement the reading for those that are interested in digging a little deeper.

Brief Primer: Broad Classification of Castings Production and Process

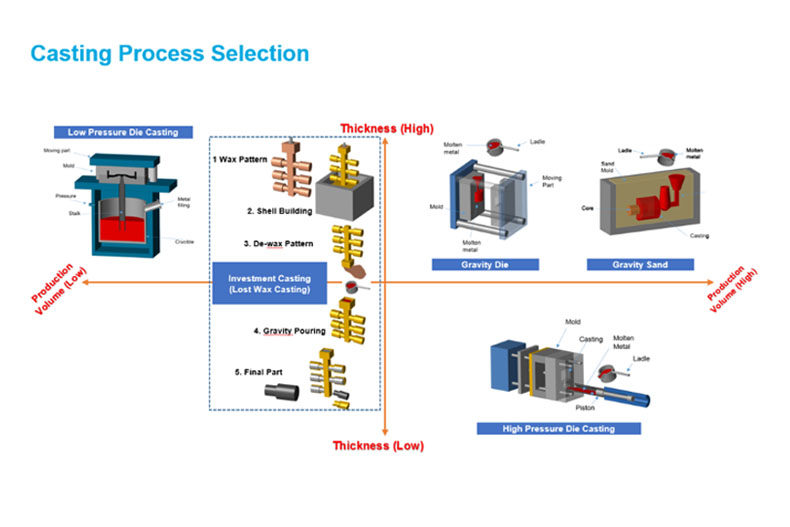

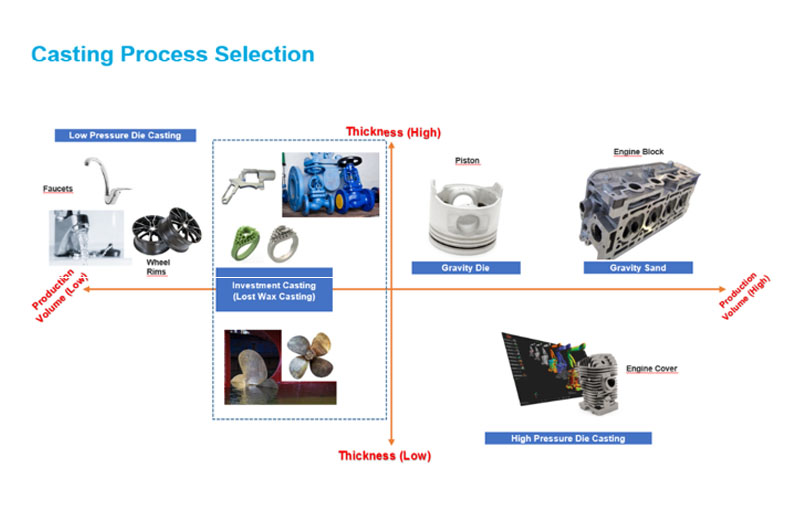

I made a very broad assessment of the various casting processes and put it into four quadrants to identify the best casting methods based on the geometry of the part (smallest sectional thickness) and the volume of production.

In the vertical axis I have the classification based on thickness and on the horizontal axis it is based on production volume. Low thickness and high volume production on the bottom right, and high thickness and low volume production on the top left quadrant. Gravity sand casting caters to high volume production for thicker parts. Investment casting spans in thickness but usually geared to lower production volume. This process is gaining traction as it well caters to make parts that are difficult with traditional methods and allows geometric freedom. You can learn more about this process here https://www.youtube.com/watch?v=wMzSS3BnMLs

Cancerous Castings

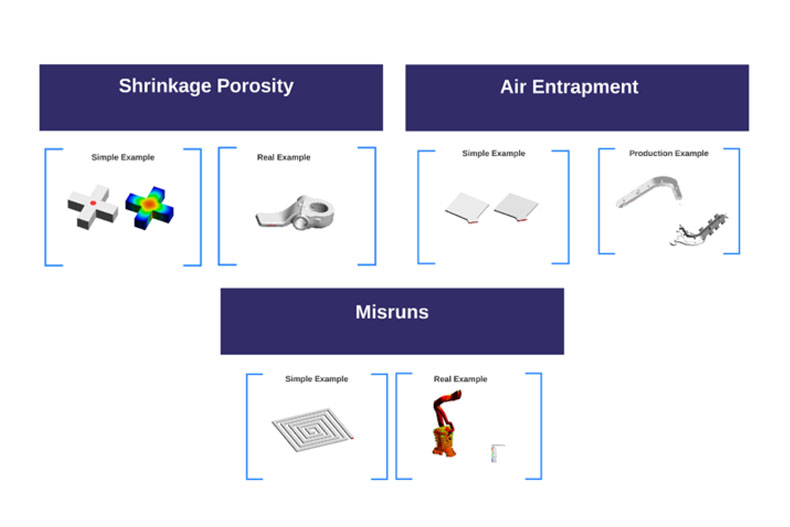

There are visible and invisible defects in castings. In my opinion those defects that are invisible can be extremely dangerous as they can rip apart the performance. Let’s walk through three defects that can typically occur in the casting process.

It is a lot better to watch the attached videos pertaining to the above defect so you can not only understand what they are but also get an understanding on how those can be identified and rectified using simulation tools like Click2Cast.

Porosity

Air Entrapment

Misruns

Hopefully the above gives a good introductory picture, of not only creating radical light weight structures that meet very specific performance requirements, but also in identifying defects in castings that can be detrimental.

With a good understanding of requirements, and the use of the right technologies we once again have the ability to catapult manufacturing of unique, high quality products helping engineers think freely and simultaneously benefiting the local economies on this interesting journey.