2 + 2 = 3.5, 4 and 6.8? – Standardizing Strength Assessment of Metal Parts

Admitting that the headline is somewhat provocative, this is the exact situation in strength assessment of components made of metals. One might think that the task of evaluating the mechanical strength of a component should be a mundane thing since machine parts made of metals have been manufactured for centuries. In practice, the opposite is true. Giving equally simulated FEA results to different engineers leads to a whole bunch of different assessment results even for a simple assessment of static strength. For fatigue strength, the situation is even worse, since by nature, fatigue strength properties scatter strongly.

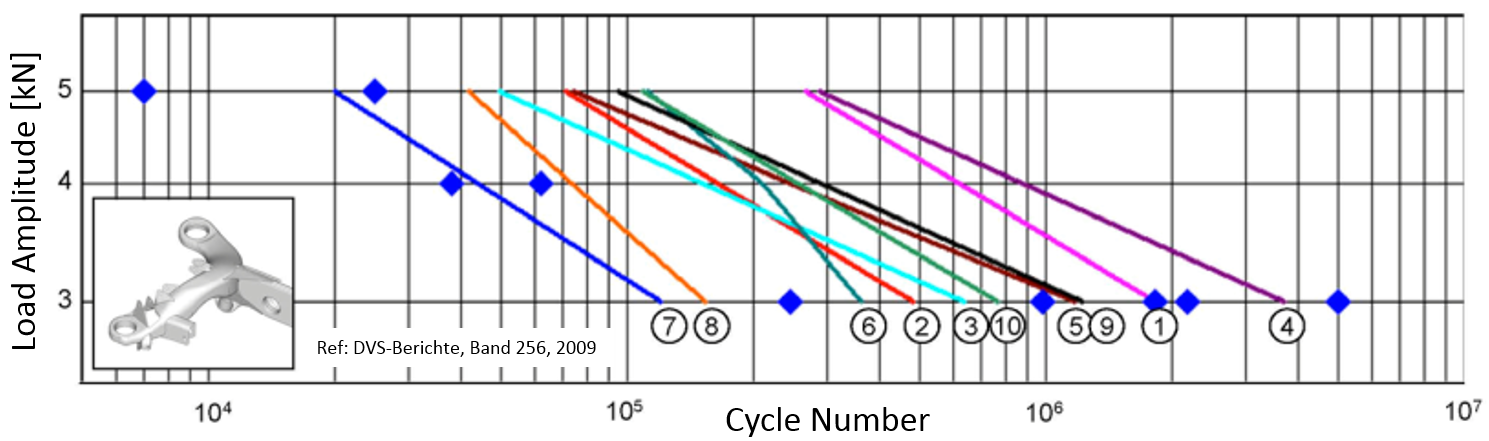

Figure 1: Results of a fatigue assessment applying different concepts and software tools

In Figure 1, results of a case study are shown where different companies where asked to predict the fatigue strength of an equal steel component with their particular approaches and software tools based on given FEA results. The assessment results differ in order of magnitude between each other as well as from the experimental result. For other problems in the same survey, the ranking of the applied methods was completely different, while the range of results obtained by the different approaches remained nearly the same. The important point here is that apart from the intrinsic problem of scattering of the real strength properties, additional fuzziness is added by undefined evaluation processes. Subsequently, comparability e.g. between assessment results obtained by an OEM and a supplier might not be given. This shows that there is not a lack of techniques and software but a lack of an agreed procedure or an applicable standard.

Such a standard should unambiguously define how to proceed in order to get a proper assessment of the static and fatigue strength alike. With respect to that, it should leave as few as possible decisions to the engineer conducting the assessment. It should be applicable in the scope of a daily business routine taking into account limited resources of time, software licenses as well as the experience of the user. Additionally, the problem of the scattering of the fatigue properties themselves should be tackled by offering material strength properties of specific grades to a certain survival probability as well as giving safety factors for particular consequences of failure.

With the so-called FKM guideline[1] indeed such a standard is available. It is a German guideline with full title “Analytical Strength Assessment of Components Made of Steel, Cast Iron and Aluminum Materials in Mechanical Engineering”. It is a comprehensive guideline with approx. 230 pages describing the static and fatigue strength assessments based on local stresses, thus it is applicable for results obtained by FEA. Unlike standards like the ASME, the FKM is not product- or industry-specific, rather it is applicable in a most general manner. The concepts outlined in the guideline have its origins back in the 60s of the last century, whereas its first edition was published at the beginning of the 90s. Now it is in its 6th revised edition from 2012. As of today, the FKM guideline is the de-facto standard at least in German-speaking countries, when it comes to strength assessment of machine parts. However, due to its mere volume and the complexities of the concepts applied, its usage for strength assessment of FEA results would be a rather tedious job. An automated solution is indispensable.

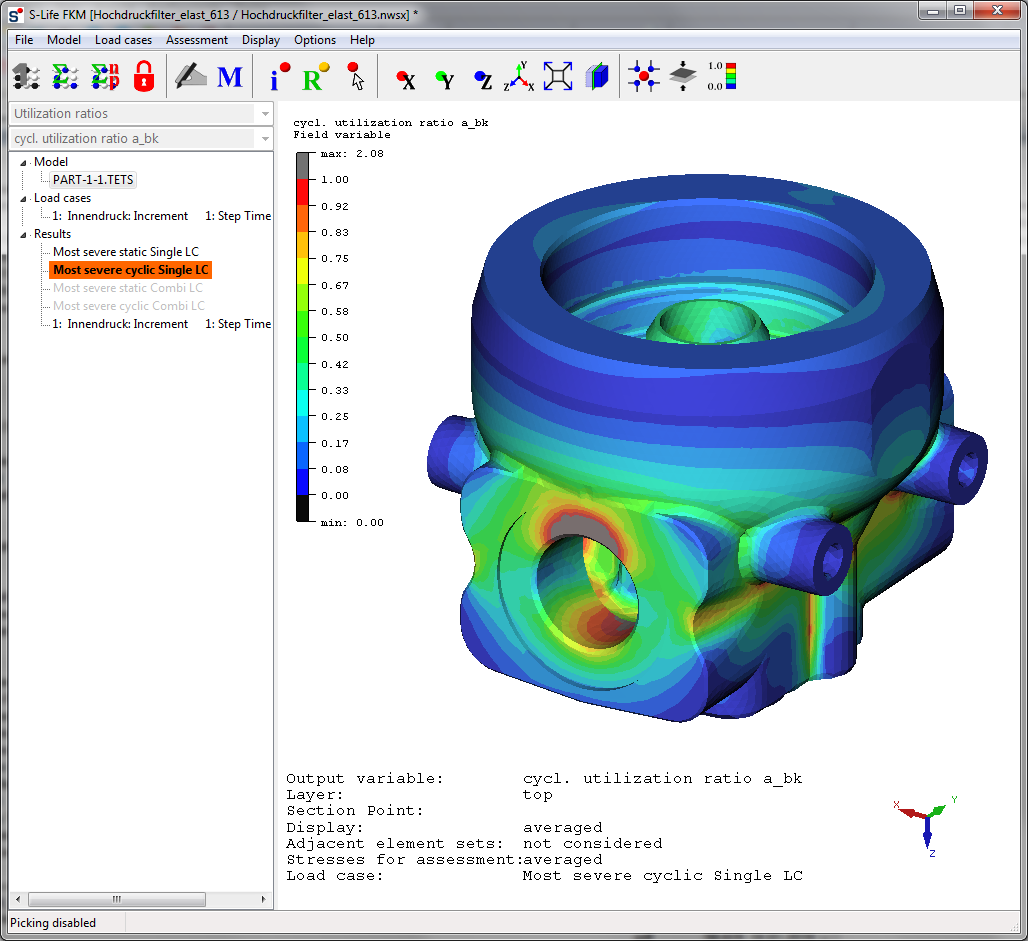

Figure 2: Example of a cast iron machine part in S-Life-FKM – Cyclic utilization ratios as contour plot

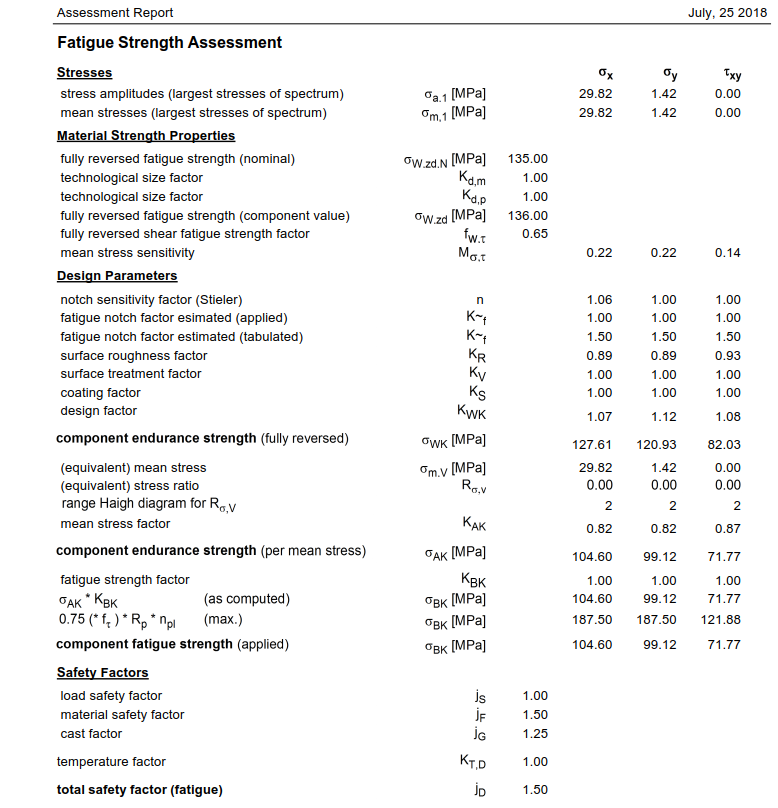

S-Life-FKM by PART Engineering is a software that enables an easy and automatic assessment of FEA results according to the FKM guideline. The software is used as a postprocessor interacting with the particular FEA software of the user. Unlike multipurpose fatigue solvers, S-Life-FKM is streamlined to exclusively reflect the FKM guideline. Therefore, with S-Life, at the push of a button the computed stresses will be processed in such a manner that an assessment of the static and fatigue strength according to the FKM guideline for non-welded parts is carried out. As result of the assessment, the static and cyclic utilization ratios will be displayed as a contour plot (Figure 2). A comprehensive numerical report of the most relevant computation results can be requested nodewise for documentation and checking purposes (Figure 3).

Figure 3: Example extract from critical node report in S-Life-FKM

The S-Life user can get the following benefits from its usage:

- Easy-to-use, even for the occasional non-expert user

- Huge time-savings compared to a manual assessment

- Reliable results according to a proven assessment scheme

- Unambiguous Go-NoGo – decisions

- Well documented results for quality assurance and customer communication purposes

Approx. 1500 grades (steel, cast iron, aluminum, cast aluminum) from the FKM material tables are completely provided by S-Life. Own materials can be added into the database. The FKM guideline can be considered as “Theory Manual” for S-Life. The guideline is available in English language as well. S-Life-FKM can be accessed through the Altair Partner Alliance.

[1] FKM = „ForschungsKuratorium Maschinenbau e.V. (FKM)“, engl. „Research Foundation Mechanical Engineering“

This guest contribution on Innovation Intelligence is written by Dr. Wolfgang Korte, Managing Director at PART Engineering, developers of CONVERSE andS-Life-FKM. PART Engineering is a member of the Altair Partner Alliance.