“When Does Simulation turn into Reality?”

With this question Dominique Moreau – Vice President of Airframe Technical Authority at Airbus opened his keynote speech at the E-ATC 2017 in Frankenthal, Germany (June 26th – 28th 2017) and went on to say that on Airbus’ latest development program for the A350XWB, many physical tests have already been replaced by numerical simulations. These have been accepted by airworthiness authorities for certification. Clearly, the transition has already happened.

We interviewed him after his talk and wanted to know about the biggest challenges for the Aerospace industry based on his point of view: Moreau listed a fast-changing technology landscape, the capabilities of new tools for the virtual development, and handling of big data. To underline the technical challenges, Moreau stated: “3D printing - we can see that it is used more and more often. We already have 3D-printed parts flying on existing aircrafts”. He further mentioned the fast evolution of composite or metallic materials and their manufacturing processes.

Regarding CAE tools he said, “Computation time is no longer a driver.” He emphasized, “Now it is the ability to use the tool and the interconnection of the tools themselves” as key aspects for the future.

Earlier this year Airbus chose HyperMesh® and HyperView® for pre- and post-processing based on a benchmark competition. Per Moreau, one of the main reasons was the efficiency of the software and its tight CAD integration. An intuitive user interface reduces training times, and the HyperWorks® license model is especially attractive for the world-wide collaboration of Airbus teams, both of which factored into the decision making.

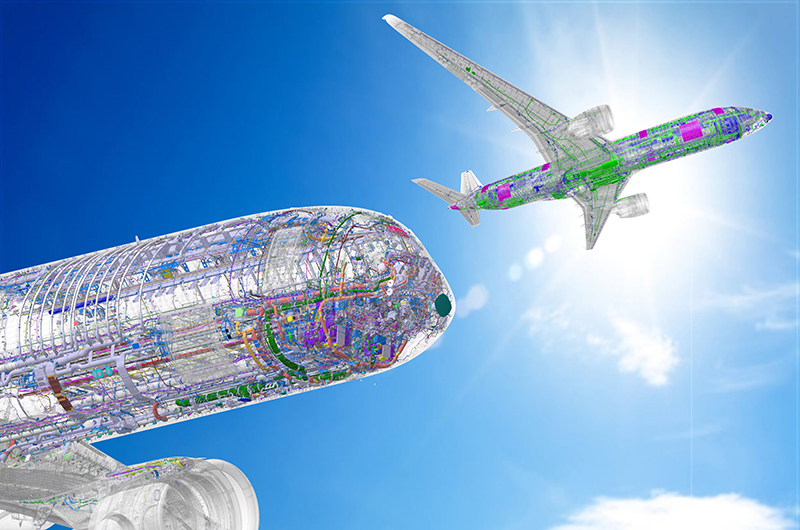

The third challenge he touched upon is smart usage of huge amounts of data (aka Big Data) produced in the design phase or later in the ‘downstream’ phase. Sharing big data is already reality in the “Digital Mockup” of CAD data (DMU). It helps to accelerate the simulation phase while resulting in better designs and enables customers to improve maintenance and fleet efficiency.

Finally, Moreau shared his thoughts on being an attendee at the E-ATC himself. He enjoyed seeing the entire spectrum of the Altair portfolio and gained lots of good ideas for the future. When asked for the most important reason on why to attend, he highlighted the efficiency aspect: “You spend one or two days there and you meet lot of people. Otherwise you will spend weeks to achieve the same result by having phone calls and video conferences with the same people.”

To view an interactive recording of Mr. Moreau 's presentation click here.