Instantly Understandable Vibro-Acoustic Results: Easier Decisions and Time Savings

This post on Innovation Intelligence is written by Francois-Xavier Bécot, co-manager and researcher at MATELYS Research Lab. AlphaCell is available through the Altair Partner Alliance.

How many days, hours or minutes does it typically take your team to make a decision about the best simulation approach for a project?

Have you ever asked yourself how much time you have to make a final decision before it’s too late, or how much time you would gain if you could understand the simulation results rather than just reading them? The underlying question is how do you target the most efficient strategy? Should you give a person a fish or teach them how to fish for themselves?

An engineering pocket calculator

What would your ideal engineering pocket calculator be capable of? It should be reactive, straightforward and include some physics, if possible. In the Computer Aided Engineering (CAE) world, Noise, Vibration and Harshness (NVH) engineers may desire to know the critical frequency of a bare structure, or the total air flow resistance of a perforated panel, etc. Do you really need finite element simulations to answer this? Would you really like to dig out your old text book to compute it? What alternative do you have?

Yet another modeling tool

AlphaCell offers another view of your daily workflow. It has been designed to answer your need to understand what is actually making the vibro-acoustic signature of your sound package.

As a user from an automotive supplier says, "AlphaCell is a great and fast tool to design our acoustic and damping treatments, which helps us satisfy our customers in the early stages of their projects. For example, within minutes we can obtain the key NVH parameters of sandwich panels and improve their behavior."

How it works

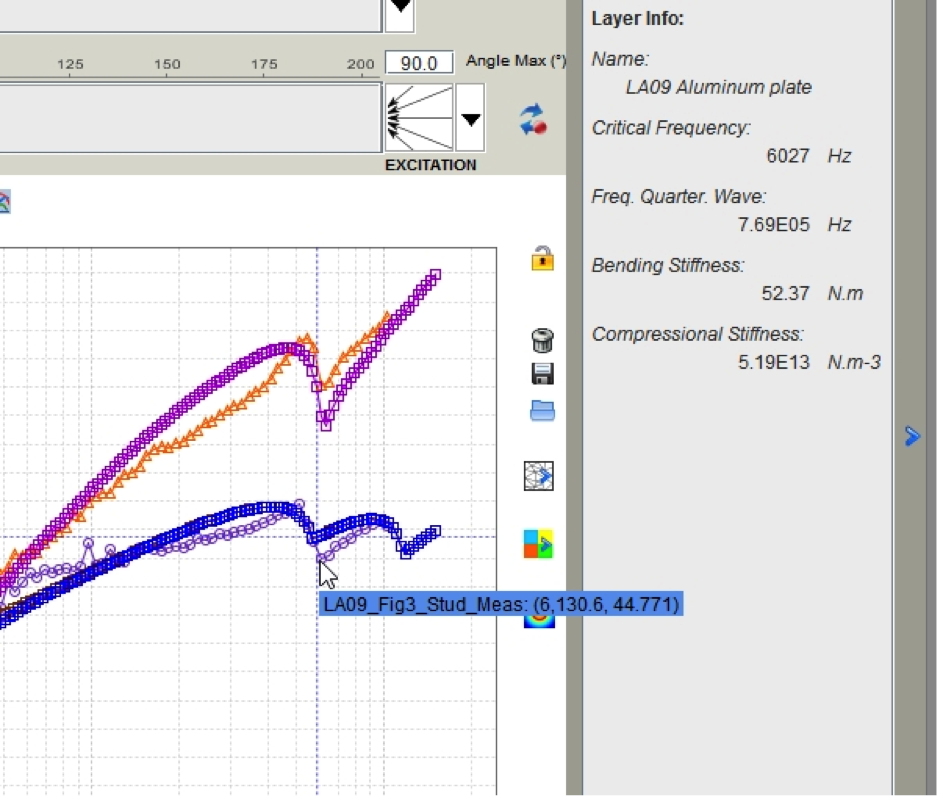

In the computation of the sound transmission loss of a studded partition, the critical frequencies may be located at first glance using the information available for this layer. The comparison between the value observed on the measured data (circled below) and that indicated by the mouse arrow corresponds well with the theoretical value given in the Layer Info panel. This response was obtained within seconds.

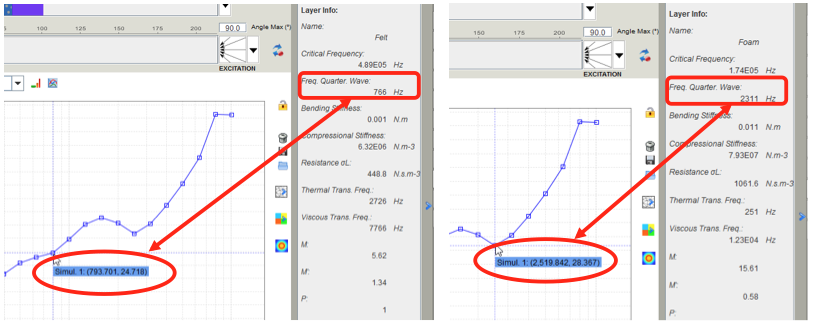

Another example is a honeycomb structure lined with a multi-layer dampening system made of a foam and shoddy. Two local minima are observed in the sound transmission loss response. Which layer weakens the response? Using the layer info, the quarter wavelength frequencies of each layer are rapidly assessed and the corresponding frequencies are identified on the spectrum.

At last, if you need to change the response by moving one of these frequencies, you will need a few seconds more to design the appropriate sound package.

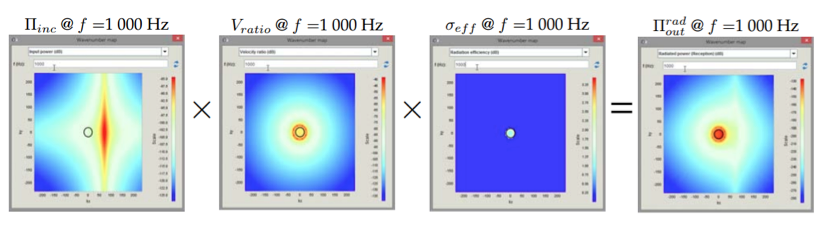

Here is a final example to show how AlphaCell helps interpret not only the dissipation mechanisms but also the characteristics of the sound radiation: AlphaCell provides the maps of the in-plane wave numbers kx and ky for a given frequency. Below is an example of these maps for a turbulent boundary layer excitation at 1000 Hz. The convection peak is clearly visible on the injected power to the plate, and this peak contains most of the excitation energy. In terms of velocity ratio (velocity out with respect to velocity in) and radiation efficiency, these maps shows the natural bending wave number, which is a circle for an isotropic plate. Finally, the last vibro-acoustic response of the structure (in terms of radiated sound power) can be viewed and is actually computed as the product of these three quantities. This shows that, while a large part of the energy is contained in the vicinity of the natural wave number, the region around the convection peak is somewhat masked. This phenomenon is well known by aero-acousticians because it makes it difficult to identify the part of the acoustic energy which is responsible for sound radiated inside a vehicle cabin, for example.

As a conclusion, we shall leave you with the comments from the director of Engineering and Technology at one of the leading material manufacturers in USA: "AlphaCell has not only drastically reduced our design cycle time, it has also allowed us to evaluate designs that would have been impractical to test due to cost, material availability, time to prototype, and available test fixtures. Using AlphaCell, we have a vast design space, and the quick computational speed (even on my laptop) allows for material parameter optimization."

Learn more about AlphaCell here.