Altair Adds Alsim PAINT SHOP to the Altair Partner Alliance

Right across industry, the development of simulation software is being shaped by common values. Best-in-class products are now driving the design process, helping users to identify the most efficient solutions not just quickly, but earlier in the journey. As projects become more complex, simulation is also facilitating wider collaboration between specialists, and putting sophisticated, high performance tools within easier reach.

For those already employing Altair software, these will be familiar characteristics and they also represent the foundations on which the Altair Partner Alliance (APA) is built. The latest addition to the APA family of partners is Engineering Software Steyr (ESS), a specialist in intelligent computational fluid dynamics (CFD) software for the automotive, mineral processing, energy, and environmental industries. Specifically, that means the introduction of two compelling software solutions: Alsim PAINT SHOP and Alsim MERGE.

Alsim Product Capabilities

Founded in 2015 and headquartered in Austria, ESS is a product of more than a decade of research and innovation. While the company’s roots lie in the automotive industry, its competencies now extend much further – as demonstrated vividly by Alsim PAINT SHOP and Alsim MERGE. Originally designed specifically for the automotive domain, the Alsim PAINT SHOP toolbox delivers a scalable suite of products that covers the whole paint shop process from pre-treatment procedures to baking operations.

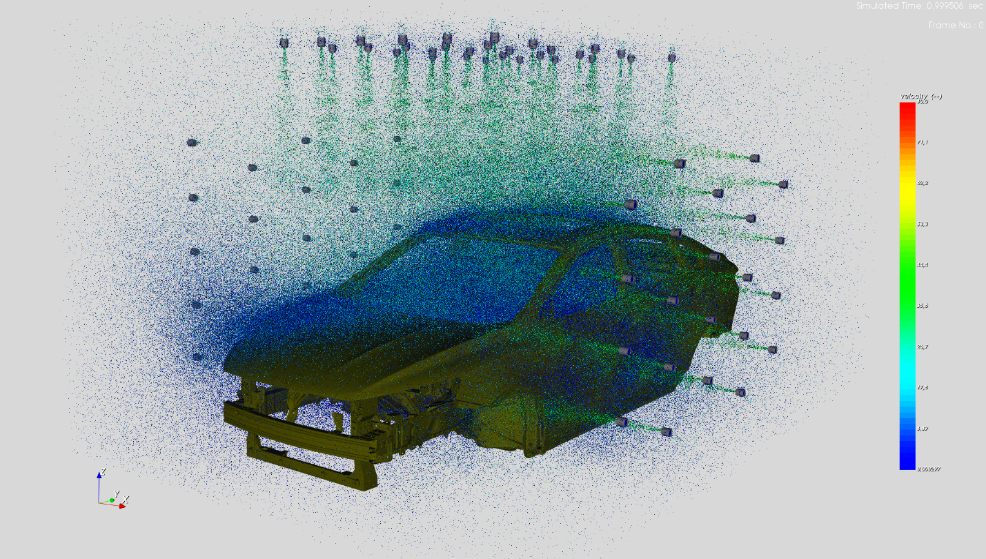

Image courtesy of ESS

As the name suggests, Alsim PAINT SHOP delivers full control over the most expensive process in the automotive manufacturing industry. Representing a genuinely unique solution, its functionality includes accurate detection of air bubbles and liquid carry-over – two of the most problematic issues in this field. Also incorporated is an e-coating tool that predicts time-related layer thickness of paint, an oven simulation for full control of the baking process, and modules for spray and rinse and PVC sealing. To ensure it can be used by expert and non-expert alike, Alsim PAINT SHOP is easy to learn, and runs on standard workstations.

“Users can simulate various processes to optimize energy consumption, finished results and quality. Together, that means enhancing brand reputation, saving resources and boosting profitability,” said Dr. Martin Schifko, chief executive officer of ESS.

Image courtesy of ES

Processing complex 3D input data in a variety of formats, Alsim MERGE provides users with simulation-ready surface meshes. Intuitive and easy to use, key benefits include ‘one-click’ data import, and fast runtimes with no requirement for manual intervention. Customizable and versatile, a range of model preparation, and meshing processes are supported.

“Users will be able to prepare complex data geometries autonomously, without any expert knowledge, and in a much shorter time frame than is possible with other alternatives,” said Schifko.

For more details on how MERGE and PAINT SHOP can help design teams deliver better results faster, click here to register for this introductory webinar, held on May 21, 2020.