Understanding EV Battery Performance with System Simulation

Guest Contributor: Graham Jackson, engineering marketing specialist Maplesoft

When designing electric and hybrid-electric vehicles, it is almost impossible to overstate the importance of batteries. There’s a growing commercial drive to increase energy density, extend battery life, and improve overall charge and discharge efficiencies in order to reduce unit costs and enhance product reliability.

How can we design electric vehicle (EV) systems to get the best performance possible out of a given battery?

A key technology in EV design – or any electric mobility design – is that of dynamic system simulation. This kind of simulation brings all the relevant vehicle subsystems together, for a system-level view of how a design performs. When connected together in a system-level simulation tool, such as MapleSim™, engineers can see how different subsystem design choices impact overall system performance. As an example, an engineer could study how various gear ratios would impact vehicle range, and make design choices to satisfy both design requirements.

Battery performance is impacted by a multitude of factors, from mechanical design to environmental conditions and driver behavior. A system-level simulation tool, contrasted with a more domain-specific design tool, can incorporate many of these factors in one environment. When everything comes together in a single simulation environment, the results are a model that delivers high-quality, actionable information to the engineers involved.

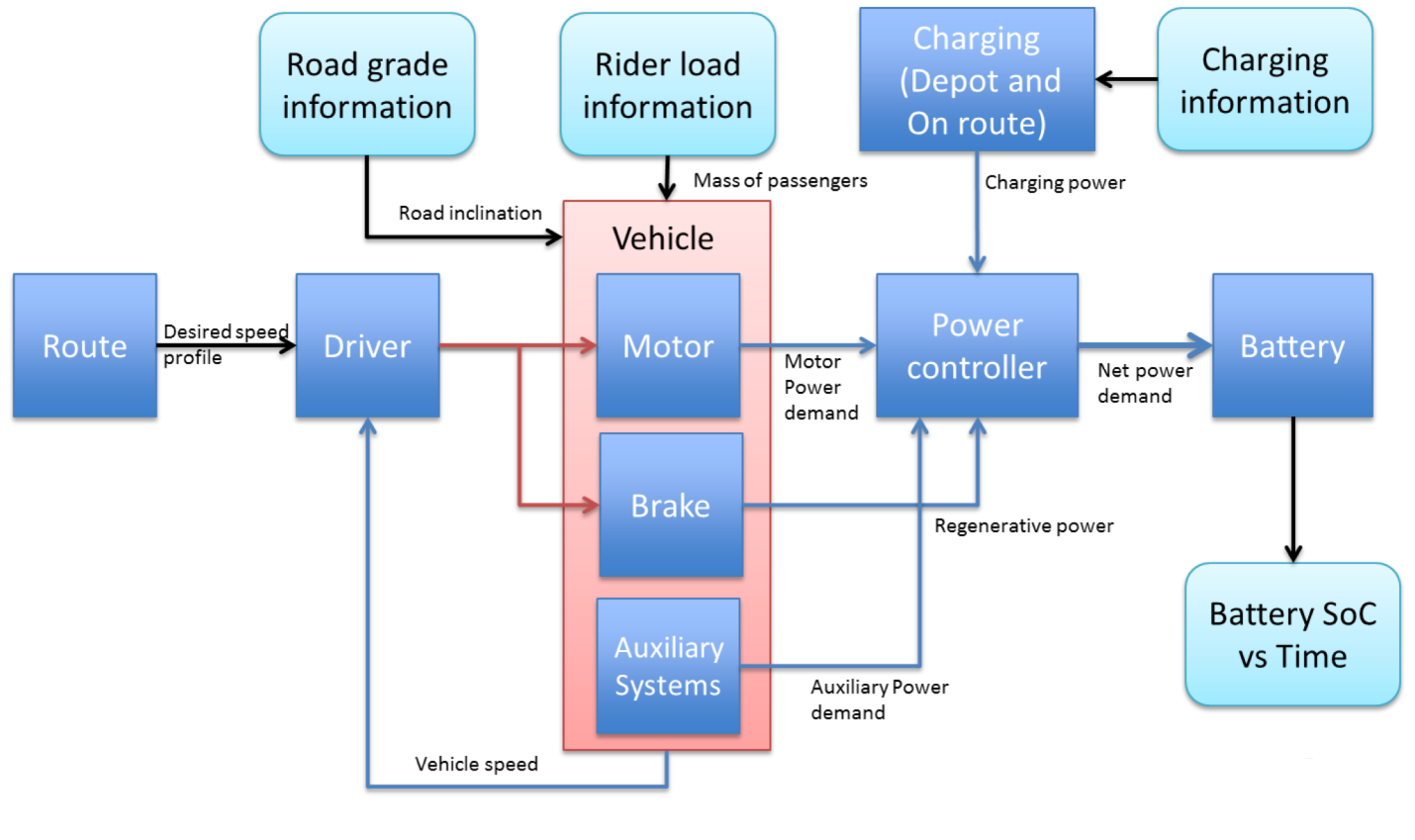

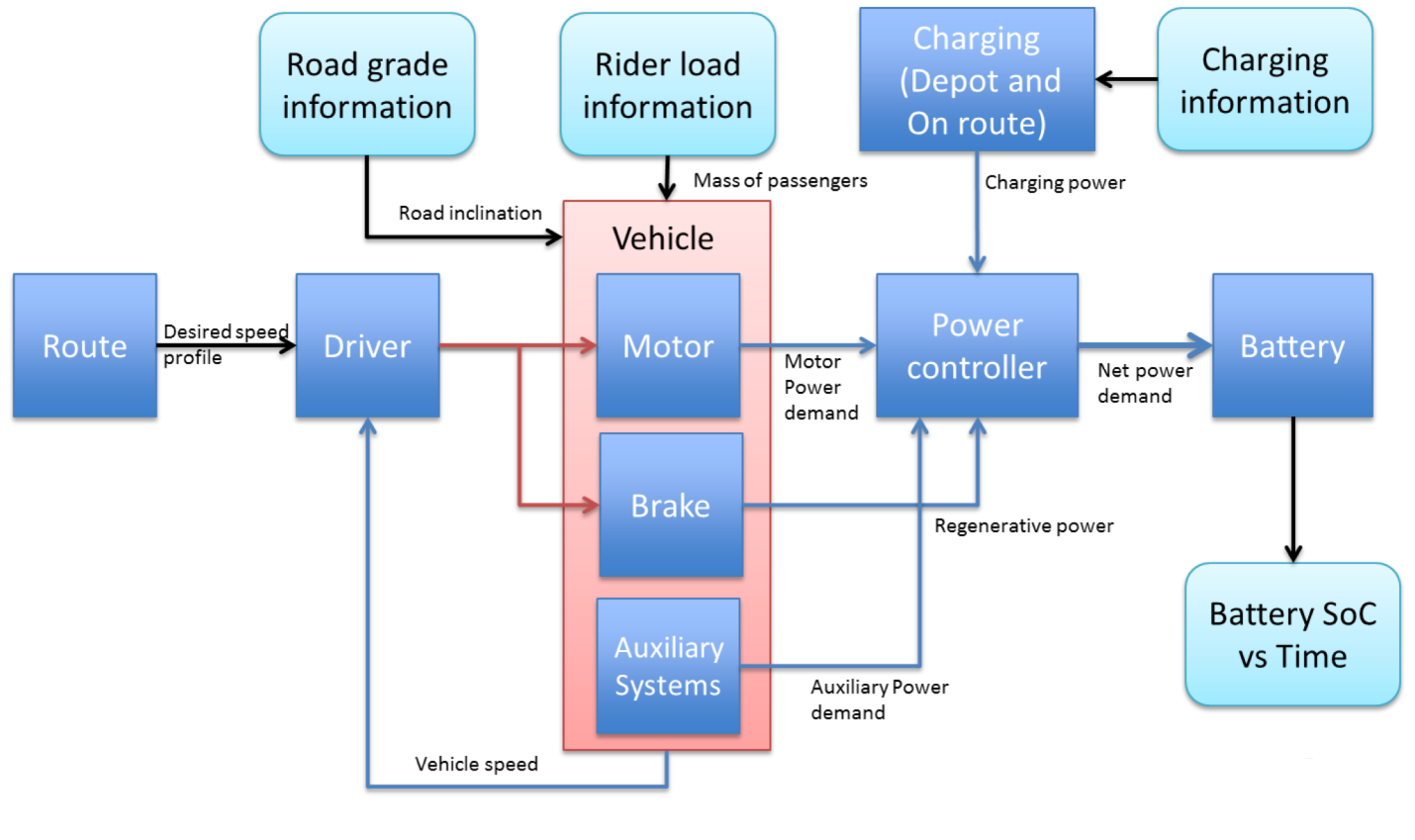

The importance of system simulation can be illustrated in a recent electric vehicle project between Maplesoft and the National Research Council in Canada. The project goal was to optimize the implementation of electric bus fleets by using system-level simulation of battery-powered busses. Bus models were created that could model not only the vehicle characteristics (battery, powertrain, tires, etc.), but also the operation of the bus for simulated test drives, charging stations, and more. By capturing so many parameters in a single model, engineers could model the impact of different batteries on a variety of bus configurations and driving conditions, and ultimately arrive at an optimal set of bus implementations.

Battery simulations come in many forms that range in their fidelity. Some of these models, known as equivalent circuit models, are commonplace methods to simplify the complex chemical reactions and resulting mathematics of a battery’s performance. For those who need more detailed battery models, electrochemical physics models can be used, which model the chemical reactions that govern a particular battery chemistry.

In an upcoming webinar, Maplesoft will introduce battery modeling and simulation, and explore how battery models can be incorporated into EV and hybrid electric vehicle (HEV) systems. A variety of battery-based systems will be explored to highlight the range of activities available when using a system-level simulation tool for electric mobility applications.

When designing electric and hybrid-electric vehicles, it is almost impossible to overstate the importance of batteries. There’s a growing commercial drive to increase energy density, extend battery life, and improve overall charge and discharge efficiencies in order to reduce unit costs and enhance product reliability.

How can we design electric vehicle (EV) systems to get the best performance possible out of a given battery?

A key technology in EV design – or any electric mobility design – is that of dynamic system simulation. This kind of simulation brings all the relevant vehicle subsystems together, for a system-level view of how a design performs. When connected together in a system-level simulation tool, such as MapleSim™, engineers can see how different subsystem design choices impact overall system performance. As an example, an engineer could study how various gear ratios would impact vehicle range, and make design choices to satisfy both design requirements.

Battery performance is impacted by a multitude of factors, from mechanical design to environmental conditions and driver behavior. A system-level simulation tool, contrasted with a more domain-specific design tool, can incorporate many of these factors in one environment. When everything comes together in a single simulation environment, the results are a model that delivers high-quality, actionable information to the engineers involved.

The importance of system simulation can be illustrated in a recent electric vehicle project between Maplesoft and the National Research Council in Canada. The project goal was to optimize the implementation of electric bus fleets by using system-level simulation of battery-powered busses. Bus models were created that could model not only the vehicle characteristics (battery, powertrain, tires, etc.), but also the operation of the bus for simulated test drives, charging stations, and more. By capturing so many parameters in a single model, engineers could model the impact of different batteries on a variety of bus configurations and driving conditions, and ultimately arrive at an optimal set of bus implementations.

The various components contained with a dynamic simulation model of an electric bus, highlighting the wide array of factors that will impact battery performance.

As in all things modeling and simulation, a model is only as good as the information and assumptions that it contains. To be confident in our simulations, especially when incorporating battery models, we need to be confident in the information we provide the model.Battery simulations come in many forms that range in their fidelity. Some of these models, known as equivalent circuit models, are commonplace methods to simplify the complex chemical reactions and resulting mathematics of a battery’s performance. For those who need more detailed battery models, electrochemical physics models can be used, which model the chemical reactions that govern a particular battery chemistry.

In an upcoming webinar, Maplesoft will introduce battery modeling and simulation, and explore how battery models can be incorporated into EV and hybrid electric vehicle (HEV) systems. A variety of battery-based systems will be explored to highlight the range of activities available when using a system-level simulation tool for electric mobility applications.