Mabe

Mabe's Continual Performance Improvement of Washing Machines with a Multi-Disciplinary Approach

Altair technology has enabled Mabe to increase the capacity of their washing machines by 35%, and the spin speed by 24% while reducing the cost per cubic foot by 10%. They have also improved the energy factor by 24%, and the water factor by 52%, while reducing the product development cycle time by 25%. By achieving these often-competing goals of improved performance, reduced cost, and accelerated time-to-market with new designs, Mabe has significantly improved its ability to compete against other appliance manufacturers.

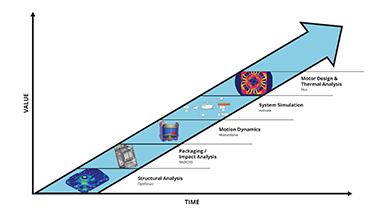

As long-time simulation users, Mabe sought to build on several stages of continual improvement over the last decade. Beginning with structural analysis in 2006, Mabe used Altair OptiStructTM to lightweight the machines as a way of reducing costs while maintaining high quality. Altair RadiossTM was used next for impact and drop-testing simulations to reduce the risk and expense of damages during shipping. Excellent gains were made, but the opportunity existed for increased value from Altair’s multi-disciplinary approach, and Mabe fully leveraged the benefits derived from simulations of ever-increasing fidelity and scope.

To meet the rising demands and evolving engineering requirements of vertical axis machines, simulation of motion dynamics became important. Altair MotionSolveTM was used to simulate the motion dynamics of the washer drum, including the balance ring and the suspension system. An idealized motor model was used to define the various spin speeds of the washing machine during agitation and spin cycles. Next, this motor idealization was removed, consistent with Mabe’s methodical approach toward ever-higher-fidelity simulations, and afforded by their shrewd use of the Altair HyperWorksTM Units licensing model. Specifically, Mabe began using Altair Activate™ for two purposes: (1) for detailed one-dimensional (1D) motor control modeling based on a block diagram approach and (2) as an integration platform for multi-disciplinary system-level simulation through coupling to Altair MotionSolve.

Greater use of Altair’s simulation

Greater use of Altair’s simulation