Altair® e-Motor Director™

Accelerating e-Powertrain Design

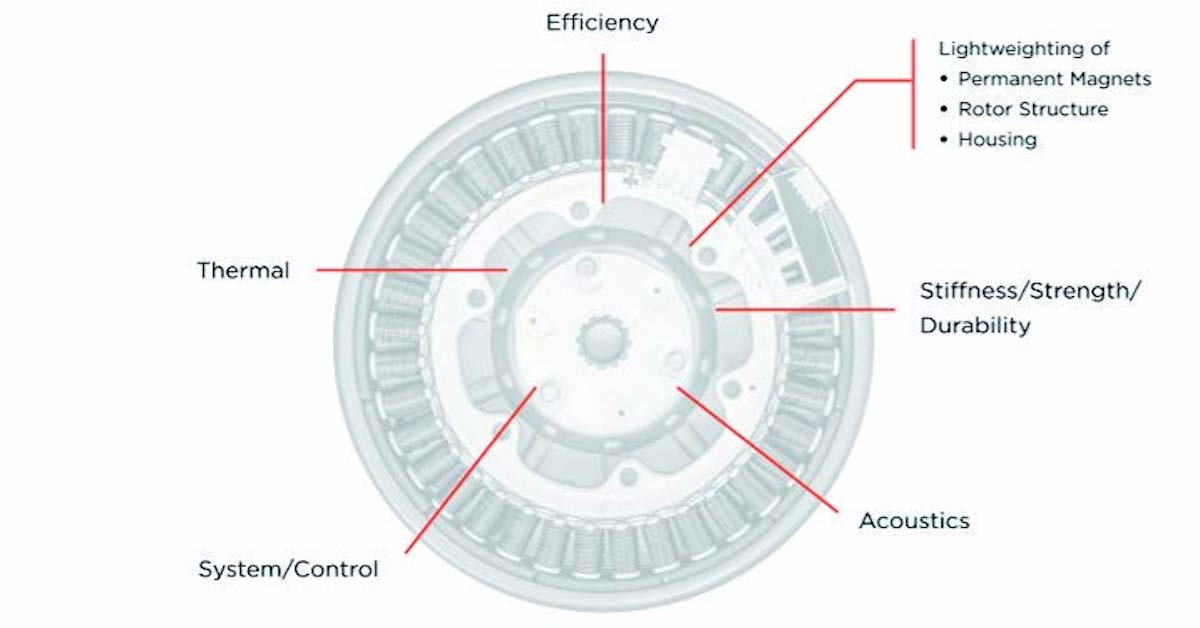

Considering the tight limits on costs and the industry’s competitive time-to-market, developing innovative electric powertrains is a challenge for any manufacturer. To solve it, Altair e-Motor Director is an efficient, robust solution that delivers competitive motor designs while considering all project requirements. Altair e-Motor Director mixes the advantages of simulation- and data-driven design to weigh conflicting constraints from multiple physics so you can accelerate the development of cutting-edge e-powertrains. Altair e-Motor Director creates, manages, and stores study descriptions for multi-domain analyses, and handles design of experiments (DOE) data associated with your design studies. It also enables optimization to identify a motor family or a specific motor based on a single DOE or multiple DOE studies.