Digital Debunking: Die Another Day - Is a Bullet Proof Vest Enough to Save Your Life?

James Bond certainly has no issue with living dangerously. If the books and movies are anything to go by, he has no apprehension about being in treacherous car chases, parasailing down waves as tall as a skyscraper (we’ll refrain from commenting about CGI quality), or risking his life in nail biting gun fights. Thank goodness for bulletproof vests, right?

On that topic, the bulletproof vest really is a feat of engineering mastery credited to Richard Davis in 1975. Tightly layered nylon with multiple interlaced fibers creates a mesh so dense, it dissipates the explosive energy of a bullet, preventing it from penetrating the weave. Davis found it difficult to convince people that his invention really did work however, so decided to prove it by actually shooting himself in the stomach! To this day, Davis has been shot more than 200 times to prove his vest is effective. Apparently, “the first one was for science, the rest was show business.” Not sure even James Bond would do that…

Do Bulletproof Vests Offer Enough Protection for the wearer?

While a bulletproof vest offers substantial protection for the wearer, there is still a very real risk of injury or even death due to the resultant forces created by a bullet or ballistic. The vest may stop a projectile, but the kinetic energy must go somewhere and unfortunately for the wearer, that usually involves their body. Because of this, companies that offer solutions in the defense fields want to investigate the effects these forces have on the human body to produce better armor and protective clothing, enhancing the health and safety of the wearer. This requires an effective testing device and accurate simulation modeling of ballistic impacts, protective clothing, and the human body.

Traditionally, testing devices like the behind armor blunt trauma rig (BABT) measure the level of personal protection, however, it is difficult to assess whether the results are applicable to a real person and not just a dummy. Unlike Richard Davis, not everyone is willing to be a test subject and shoot themselves to see if newly designed protective clothing really works.

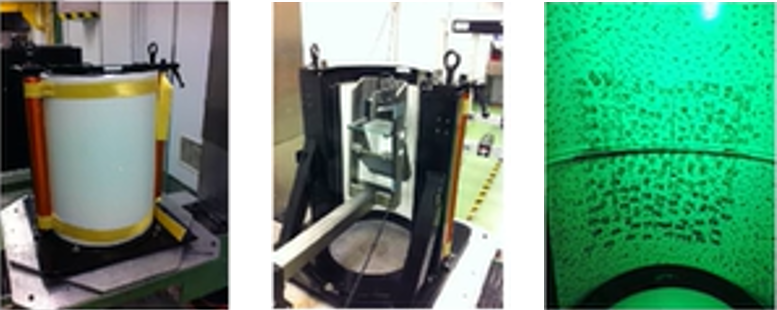

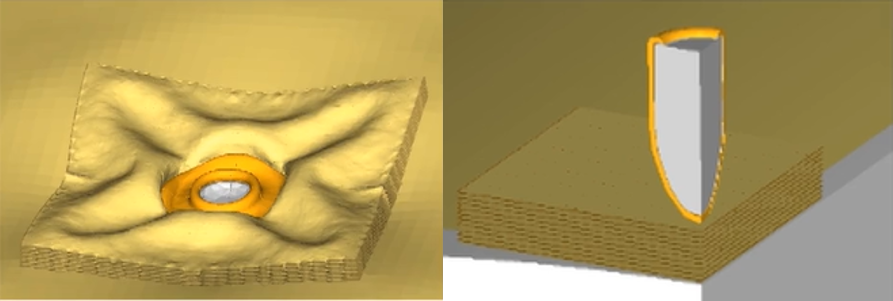

DuPont, a materials manufacturer and producer of protective clothing, developed a more accurate testing device dubbed the Dynamic Trauma Analyzer (DTA). This device consists of a semi-cylinder-shaped thorax surrogate made of hyper elastic material, a steel framework that supports the surrogate and protective solution, and a measuring system. One of the main issues with other testing rigs is that you only have access to half the story, measuring just the residual deformation of gelatine blocks. The DTA gives engineers access, quite literally, to the other side by recording the full dynamic biomechanical response of a body area such as the chest, with displacement and velocity histories.

To design more effective protection solutions, DuPont was interested in numerically reproducing the experiments of the DTA, so French engineering company CEDREM helped in a collaborative study to simulate the bullets, protective solution, and DTA behavior.

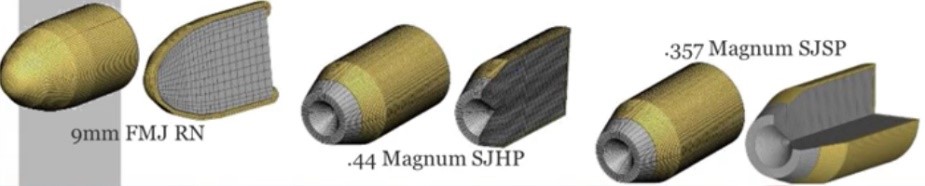

Representing the Bullets

For this study, DuPont used three different bullets: a 9mm, a .44 Magnum, and a .357 Magnum, the numerical models of which were already available at CEDREM. (Incidentally, these bullets belong to guns that have been used in various James Bond films). All three of these bullet types are composed of a lead core inside a copper envelope, meshed with solid elements.

Representing the Bulletproof Vest's Protective Material

For this study, CEDREM investigated a mesoscopic and macroscopic approach to build an accurate numerical model of this material. First, a macroscopic approach was taken using Altair Radioss™ to build a model consisting of a single layer of shell elements, while fully exploring other shell formulations and material load possibilities. The results of this were then compared to a mesoscopic approach using CEDREM’s KTex Family, a set of tools dedicated to modeling composite materials precisely at the scale of the yarn. As the mesoscopic and macroscopic results were almost identical, the macroscopic approach was taken to reduce calculation time.

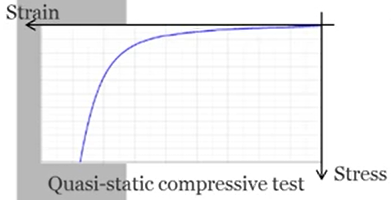

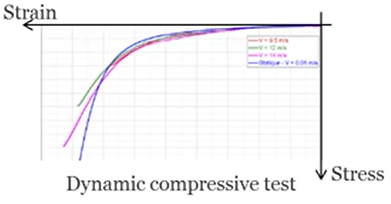

Representing the DTA Material

As the material of the DTA consisted of hyper-elastic rubber, both quasi-static and dynamic compression tests were performed to assess the strain rate dependence, making it possible to build an accurate numerical model. The trails showed no strain rate dependence, leaving CEDREM engineers feeling confident that their simulated model was accurate.

Bulletproof Vest Validation

The next step was to validate the numerical models. The results of a 9mm bullet impact were compared to simulations that accurately represented the DuPont product and bullet impact. From the real-life tests, the maximal deformation of the DTA back-face was 22.2mm at 4.1ms, compared to the simulation results of 22.6mm of deformation at 3.79ms, leading the team to believe the numerical model was accurate. Additionally, the number of perforated layers of protection when impacted showed very similar results. This process was also performed using the .44 Magnum and a .357 Magnum bullets, both of which showed accurate results.

As any James Bond fan will tell you, the 9mm is the closest caliber ammunition to Bond’s preferred Walther PPK. Those larger .44 Magnum calibre rounds are reserved for special situations necessitating extra power, like in the rescue of Solitaire in Live and Let Die. Virtual testing supported by lab testing is important to ensure protective clothing is safe for a range of ammunition sizes.

HUByx

Another one of CEDREM’s tools is HUByx (Hermaphrodite Universal Biomechanical XY), a finite element human body model complete with accurate representations of most internal organs, created from CT scans. This tool was developed specifically for defence applications, focusing on blunt impacts and blast loadings, making it possible to measure the propagation of pressure inside the human body.

For the purpose of this study, data collected from bullet impacts of the DTA were used to produce simulations with HUByx to investigate how the human body would react under such conditions while wearing the protective clothing.

Depending

on the impact location, the human body offers some variability in the way in which it reacts. For example, an impact to the ribs produces a different result to an impact to the stomach. CEDREM took this into account and ran simulations for both outcomes

to analyze the results.

Initially, the displacement of the lungs was recorded as the DTA represents this displacement. However, as the human body offers some variability depending on the impact location, it was more consistent to study the displacement of the ribs or skin.

Simulation and Data-Driven Design

The results of this study show a good correlation between what was measured using these numerical tools and the experimental device. Being able to test protective clothing in both a physical and virtual environment allows product designers

to explore options, validate performance, and confidently produce products that will meet the challenges of their users. These simulation and data-driven decisions make it possible to produce products that can improve the chances of saving someone’s

life. The potential for this technology to be applied to other applications with the defense sector is very high.

Circling back to our original question, is a bulletproof vest enough to save your life? Well, it depends. As we’ve

established, a bulletproof vest can stop a bullet, but the forces created by this could lead to injury or death for the wearer. What’s more, the location of impact can make a huge difference to the type or severity of injury.

By implementing the technology discussed however, a clearer and more detailed picture is possible for product designers, giving them insights that they can incorporate in the design phase. Having access to results like this allow product designers to investigate the effectiveness of their product and optimize accordingly. It’s no secret James Bond had access to some cutting-edge technology but in our books, testing the effectiveness of protective clothing from ballistic impacts by incorporating an accurate finite element model of the human body is pretty cool!

CEDREM's KTex Family and HUByx tools are available to Altair users through the Altair Partner Alliance.