Why It’s Time for EVs to Slim Down

Electric vehicles (EVs) are central to the global decarbonization effort, as shown by the major investments OEMs have made to electrify their lineups, and the way customers are buying EVs in record numbers. The governments of the European Union, Canada, the United Kingdom, and California have committed to phasing out sales of fossil-fueled vehicles by 2030 or sooner. There’s a lot to be enthusiastic about in sustainable transportation, but there’s still a major hurdle obstructing a greener future. Because even though EV technology has developed at an astonishing pace, EVs remain much heavier than their combustion engine counterparts.

The EV weight dilemma is laid out in the recent Nature article, “Make electric vehicles lighter to maximize climate and safety benefits.” Since 1990, the mass of cars, sport utility vehicles (SUVs), and pick-up trucks has increased, and consumer demand for pick-up trucks and SUVs is at an all-time high. Electrifying these bulkier models exacerbates the weight issue. An EV replaces combustible, energy-dense petroleum engine with a bulky battery and the additional structure needed to support it during impact scenarios; as an example, Ford’s new electric F-150 Lightning pick-up is more than 700 kg heavier than its gas-powered predecessor.

The Problem with Added Weight

But why worry about extra mass at all? The answer lies in the relationship between vehicle weight and safety. According to an Oxford study, the likelihood of passengers being killed in a collision with another vehicle increases 12% for every 500-kg difference between vehicles. Weight disparities between EVs and combustion-engine models could increase the chances of death in collisions.

Secondly, despite the fact that EVs eliminate carbon emissions, heavier vehicle weight still has a significant environmental impact. Heavier vehicles wear tires quicker and therefore require more materials and energy to build and propel them, which generates pollution elsewhere.

As if OEMs didn’t need another reason to prioritize lightweighting, governments are beginning to impose new taxes on heavy cars to reduce emissions. In 2020, France’s environmental minister announced that any car weighing more than 1,800 kg would be taxed at €10 for every additional kg.

Discovering Lightweighting Solutions

As a result, OEMs are turning to computer-aided engineering (CAE) to realize their lightweighting goals.

The mass of an EV battery is directly correlated to its vehicle’s range requirements. To satisfy consumer demand for range between charges, the added weight of the battery is more or less fixed for vehicle designers under current battery technologies. This leaves the body structure, interior, and e-propulsion system as the main focus areas for lightweighting.

For vehicle frames and battery support structures, technologies like topology optimization help engineers develop structures with minimal mass and maximal stiffness while considering design parameters like expected loads, available design space, materials, and cost. Simulation-driven design also lets companies explore alternative materials like laminate composites in vehicle components. Engineers can access detailed material properties and test their impact on vehicle-level performance well before the physical prototyping stage.

To see current pioneers in automotive weight saving in interior and e-propulsion systems, look no further than the winners of the 2021 Altair Enlighten Award, a series of awards that celebrate advancements in lightweighting and sustainability.

In the Sustainable Product – Vehicle category, the battery-electric Ford Mustang Mach-E was given top honor for using 10 plant-based sustainable materials in production. The Mach-E features a soyfoam headliner, kenaf door bolsters, Miko synthetic suede, and coffee-chaff head and taillights that are 20% lighter and require 25% less energy to produce.

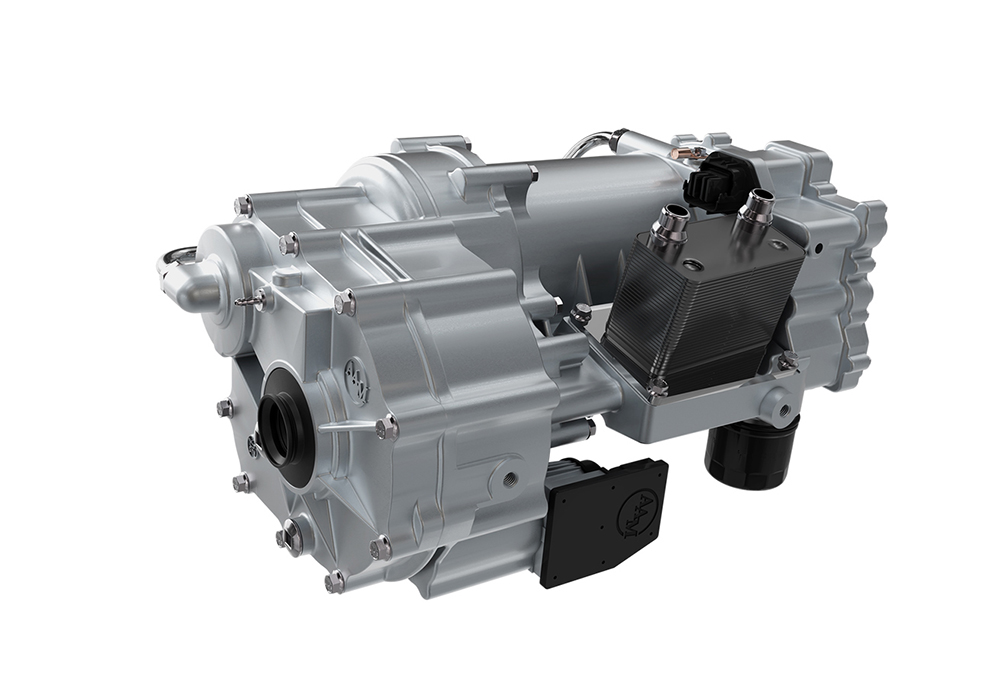

American Axle & Manufacturing won the Future of Lightweighting category with its electric drive unit (eDU) that’s 25% lighter than similar units on the market. Integrating the electric machine, gearbox, and inverter in a compact package, and eliminating the high voltage cables, the eDU also has a higher power-to-weight ratio than competitor products. Though the technology hasn’t yet been employed in commercial production platform, AAM’s eDU promises significant cost and mass savings in hybrid and battery-electric light- and medium-duty vehicles.

Research continues on battery technology to reduce weight per kilowatt-hour, yet vehicle manufacturers continue to find new and innovative lightweighting strategies. Though many challenges remain in the quest to reduce electric vehicle weight, simulation-driven design augmented by artificial intelligence (AI) and high-performance computing (HPC) give engineers greater insight than ever. These technologies let designers create and assess innovative next generation architectures by using simulation to inform vehicle architecture, manufacturing processes, material selection, and platform strategies. If you’re interested in accelerating your e-mobility development and implementing simulation-driven lightweighting strategies, visit https://www.altair.com/e-mobility/.