Applications of Reverse Engineering for CAE Data Preparation

Creating CAD data from physical objects (reverse engineering hereunder) can be time consuming and labor intensive. Moreover, each use case has different expectations for the data. For example, some use cases demand higher quality of the CAD surfaces than others.

So, what exactly are the use cases for reverse engineering? A common use case is for re-manufacturing. In other words, creating machining ready CAD models to be manufactured with machines. This use case requires high quality surfaces with accuracy that is worthy of being used to create a cutter path for machining.

Another use case is for CAE data preparation. CAE models must be prepared using reverse engineering. For example, when a manufacturer is conducting analysis of past products where original CAD might be lost or does not reflect the actual existing product. There are also cases early in the design phase where designers would like to perform manufacturing analysis based on clay models that are created. Furthermore, there are some cases where there are CAE needs for products that are not designed by themselves, such as that of other players in the industry.

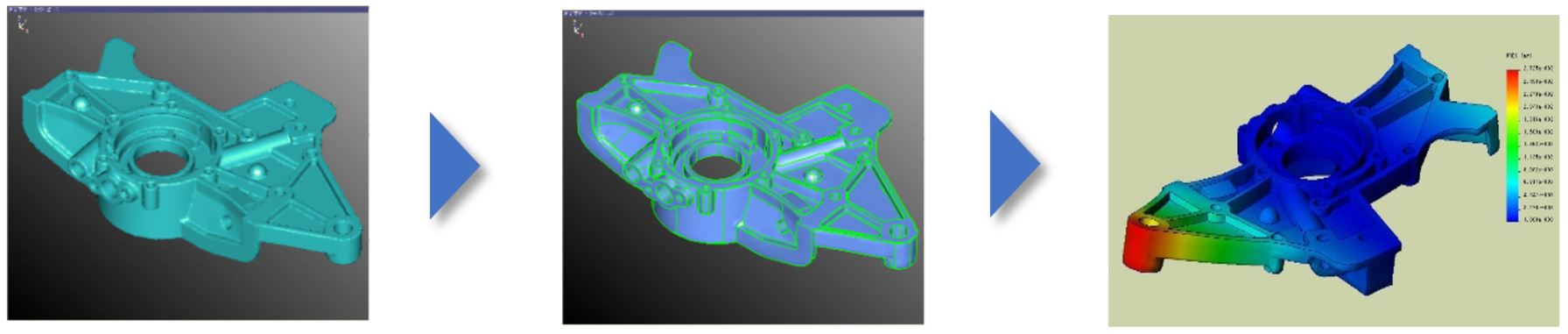

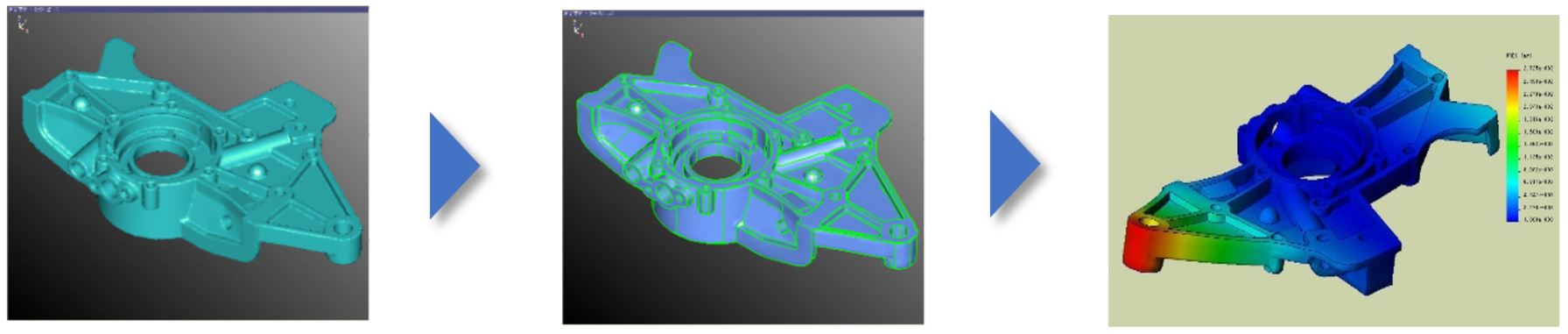

CAE analysis example workflow with reverse engineering

CAE analysis example workflow with reverse engineering

(left: scanned polygon data, center: CAD data, right: CAE analysis result)

In each situation, CAD models are created for meshing to be used for simulations such as strength analysis. Generating surfaces on CAD systems is an important factor for more accurate and usable analysis. Also, the surface quality is not the top priority for this use case and therefore easier and time efficient methods of reverse engineering are in demand.

CADdoctor, which is available through the Altair Partner Alliance is a tool to help users with reverse engineering, especially in CAE data preparation use cases. CADdoctor automatically generates CAD surfaces that are practical for simulation without concern of differences in degree of perfection depending on the engineer. There have been examples where over 75% of the lead time was reduced for CAD surface creation.

Interested in learning more about CADdoctor? Check out this on-demand webinar "CADdoctor Use Cases for Ideal CAE Data Preparation" and visit the CADdoctor information page to see its use cases in reverse engineering and other applications.

This guest contribution on Innovation Intelligence is written by Shun Higashide, Global Business Analyst at Elysium. Elysium’s 3D data translation software, CADdoctor, is available through the Altair Partner Alliance.

So, what exactly are the use cases for reverse engineering? A common use case is for re-manufacturing. In other words, creating machining ready CAD models to be manufactured with machines. This use case requires high quality surfaces with accuracy that is worthy of being used to create a cutter path for machining.

Another use case is for CAE data preparation. CAE models must be prepared using reverse engineering. For example, when a manufacturer is conducting analysis of past products where original CAD might be lost or does not reflect the actual existing product. There are also cases early in the design phase where designers would like to perform manufacturing analysis based on clay models that are created. Furthermore, there are some cases where there are CAE needs for products that are not designed by themselves, such as that of other players in the industry.

CAE analysis example workflow with reverse engineering

CAE analysis example workflow with reverse engineering(left: scanned polygon data, center: CAD data, right: CAE analysis result)

In each situation, CAD models are created for meshing to be used for simulations such as strength analysis. Generating surfaces on CAD systems is an important factor for more accurate and usable analysis. Also, the surface quality is not the top priority for this use case and therefore easier and time efficient methods of reverse engineering are in demand.

CADdoctor, which is available through the Altair Partner Alliance is a tool to help users with reverse engineering, especially in CAE data preparation use cases. CADdoctor automatically generates CAD surfaces that are practical for simulation without concern of differences in degree of perfection depending on the engineer. There have been examples where over 75% of the lead time was reduced for CAD surface creation.

Interested in learning more about CADdoctor? Check out this on-demand webinar "CADdoctor Use Cases for Ideal CAE Data Preparation" and visit the CADdoctor information page to see its use cases in reverse engineering and other applications.

This guest contribution on Innovation Intelligence is written by Shun Higashide, Global Business Analyst at Elysium. Elysium’s 3D data translation software, CADdoctor, is available through the Altair Partner Alliance.